How Flexible is Flexible Molding?

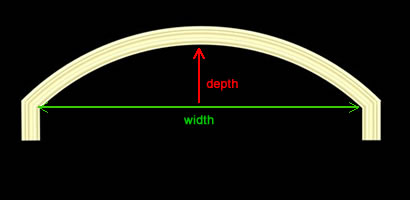

In Brief: Bending flexible molding is similar to bending a leather belt, when wrapped around your waist (bending in the “easy” direction) it is very flexible but if you were to lay it flat on a table and try to make an arch (bending “the hard way”), you won’t get very far before it starts to kink and twist. To avoid this problem when ordering for arches, we will typically pre-curve the molding to the approximate size of the arch. This is why we may ask for the dimensions of your arch when ordering. After pre-curving the flexible molding can still be adjusted to fit a range of sizes.

Details: The flexibility of each molding is different. The smaller the molding, the more flexible it is.

Flexible molding can also be applied in various ways. We refer to these applications as “bending the easy way” and “bending the hard way”. You can think of the “easy way” as bending flexible baseboard around a column. The “hard way” would be applying flexible Casing to a half circle window.

When bending any flexible molding in the “hard” direction, it is always recommended to have the flexible molding pre-curved to the dimensions of the arch. Flexible Crown Molding should be pre-curved due to the angle at which most crown molding is installed.

Examples:

• ¾” X ¾” Flexible Quarter Round would bend around a 1 gallon paint can. This application does not usually need pre-curving.

• ¾” X 3-1/2” Flexible Base Molding would bend around a 1 gallon paint can in the “easy” direction but would require pre-curving if used on an arch.

• All Flexible Casing Molding when used in an arch application (bending “the hard way”) should be pre-curved.

• All Flexible Crown Molding should be pre-curved.

Exceptions and Limitations:

• Large gradual curves may not require pre-curving and very small, tight curves may not be possible at all.

• Curves that are irregular in shape such as elliptical or oval arches, may require a template for pre-curving which carries a 20% template charge.

• Even with pre-curving there are limitations as to how much the flexible molding can be curved. The “rule-of-thumb” is 3-1/2 times the width of the molding. For example, if a flexible Casing were 3-1/2 inches wide, the minimum radius for pre-curving would be approximately 12-1/4 inches. This minimum is dependent upon the thickness as well as the width. Thicker moldings will not be as flexible and other issues such as molding shape may also limit the flexibility of the molding.

• Our “Perfect Fit Order Wizard” will walk you through the ordering process for your flexible molding and help you avoid the common pit falls of ordering flexible molding. If there is any question regarding your application, please contact us and we will be happy to assist you.